Description

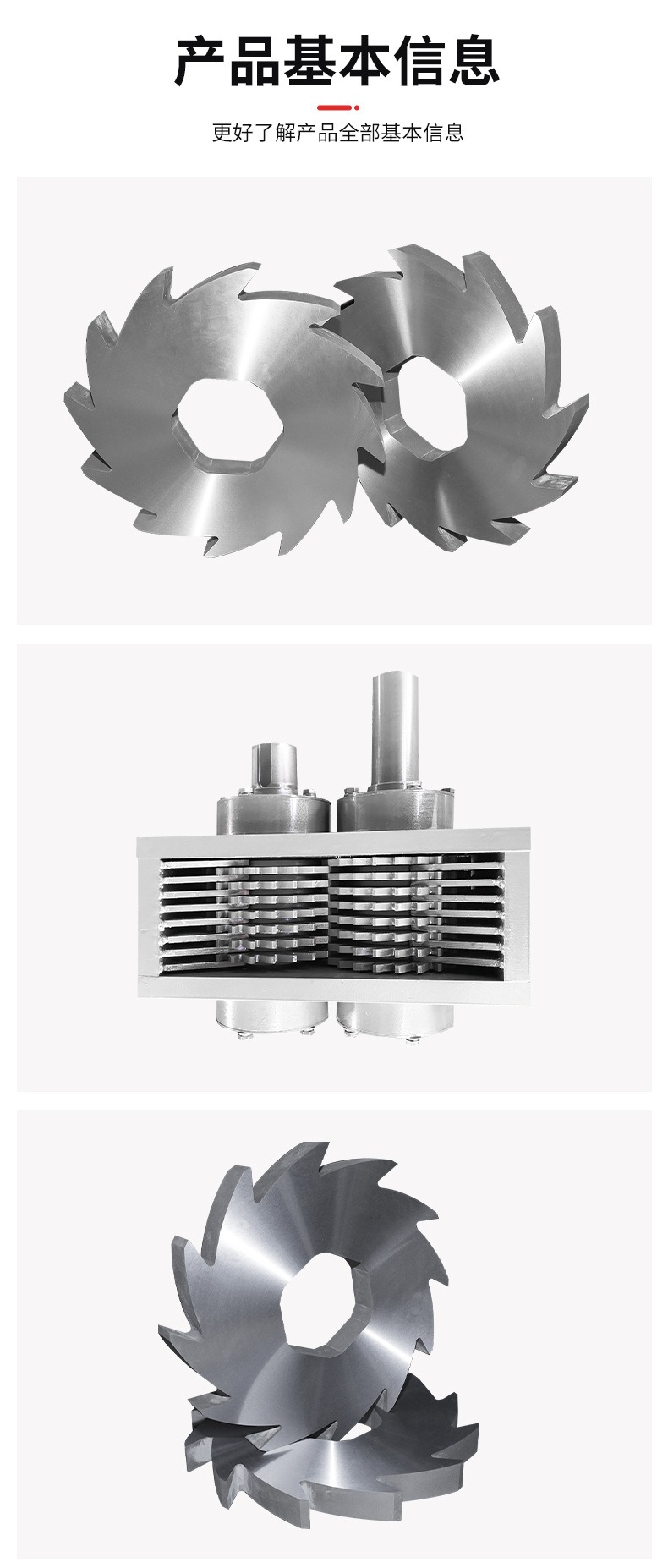

Shredder blade Single-double axis plastic crushing domestic waste metal small square knife slow shredding box crushing knife

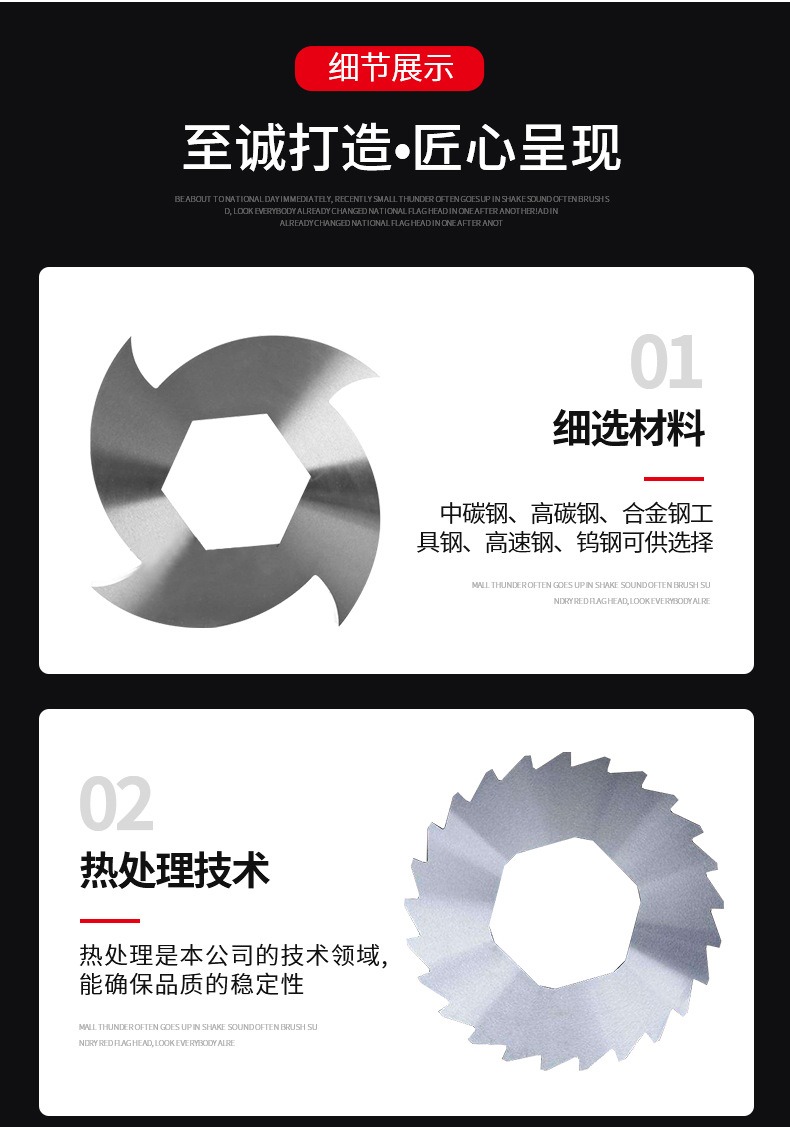

1. Material: high quality national standard steel, can be customized according to customer requirements

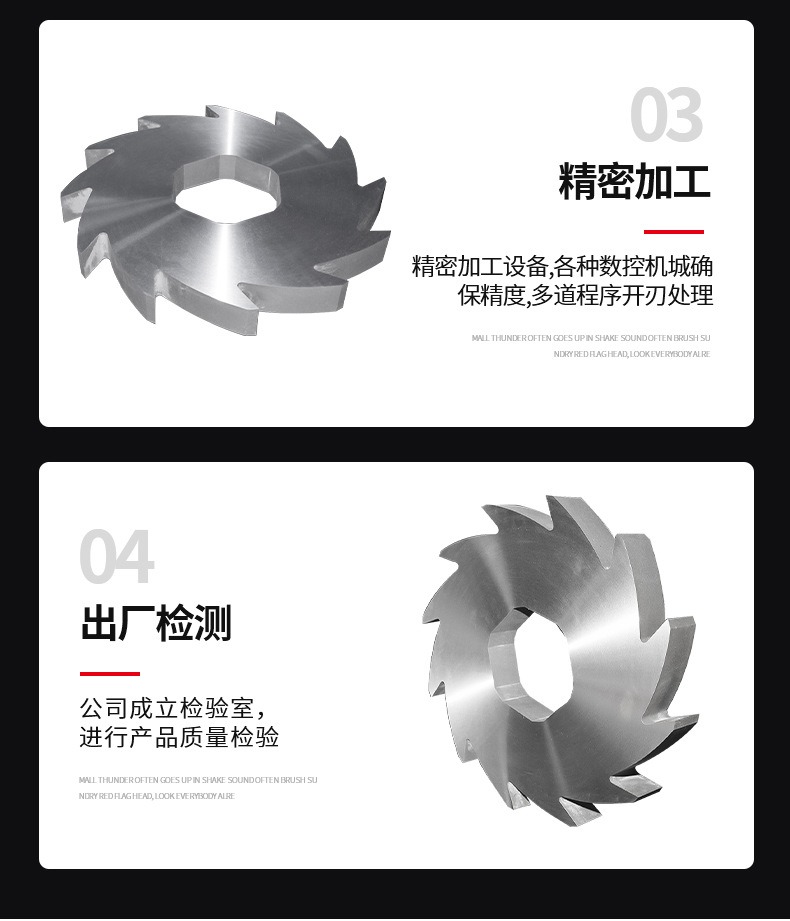

2. Product size: Common size is complete, can be customized

3. Product features: small tolerance, accurate size, short cycle, material guarantee.

4 Product use: ceramics, printing machinery, paper industry, carton, forestry, rubber, plastics, food machinery, textile, electrical appliances, light industrial machinery, aluminum foil, metallized film, tobacco, cigarette machinery, packaging materials, film, electronic appliances, wire, cable, shipbuilding, chemical fiber, glass fiber, textile, feed, paper tube, forestry, woodworking machinery, plastic crushing, edge sealing, medium sealing machinery Bottom sealing bag making machine, wood processing, food packaging, paper making, aluminum foil slitting, metallurgical machinery, medicinal materials, rubber and other industries.

Shredder blade:

shredder blade is an important part of the shredder machine, shredder blade is good or bad directly affects the processing of waste materials, according to the classification of shredder, shredder blade is divided into single-axis shredder blade and multi-axis shredder blade (including two-axis shredder blade and four-axis shredder blade).

Single-axis shredder blade:

the single-axis shredder blade is installed on the shaft of the single-axis shredder, so it is called the knife. The shape is square, the four sides of the knife edge are curved, the middle tapping hole, the part from the knife edge to the middle hole is concave inward, and the tool is used with the fixed tool on the tool holder.

Multi-axis shredder blade:

multi-axis shredder blade is a claw knife, installed on the two-axis or four-axis shredder, generally can be divided into 3 claw shredder blade, 8 claw shredder blade, 12 claw shredder blade and so on. By pulverizing, tearing and extrusion to reduce the size of the material, this shredder blade is widely used in the crushing of waste plastics, waste rubber, wood and other large volumes of waste.

Blade material:T10, 9CrSI, 6CrW2Si, Cr12MoV, H13, alloy steel, etc

1. Carbon bonded tool steel: carbon bonded steel is generally selected 65, 75 steel, T8, T10 and other materials, the heat treatment hardness of the blade produced by this material is within the range of HRC57-59 degrees, suitable for ordinary low carbon cold rolled sheet, ordinary A3 sheet and waste recycling shear, which is characterized by low cost and suitable product price.

2. Low alloy tools: low alloy tool steel blade commonly used materials are: 6Crw2sl, Cr5Mo1V9CrSi, Cr12MoV, etc., the heat treatment hardness of the blade is HRC58-62 degrees, specially cut stainless steel, suitable for hot rolled plate, stainless steel, medium and thick plate shear.

3. Alloy tool steel: Alloy tool steel cutting machine blade materials are: 4Cr5MoSiV1 (H13K)7Cr7Mo2V2Si9 (LD), W6Mo5Cr4V2(6542), H13 and so on. The blade of this material is used for hot-rolled billet, hot shear medium and thick steel plate, etc., which is characterized by high temperature resistance and not easy to annealing, and is used for hot rolling and hot shear process in steel mills.