Description

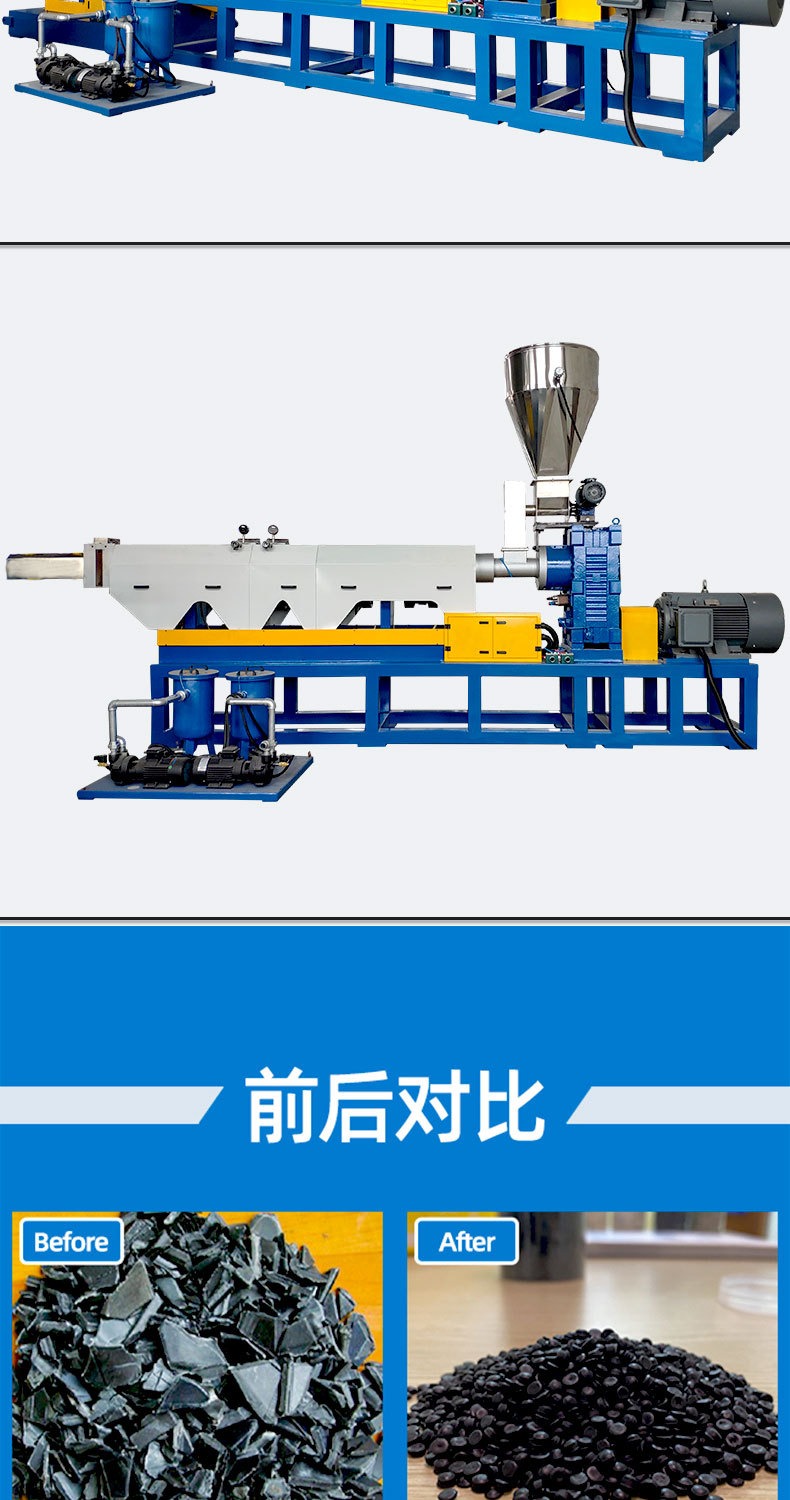

Plastic pellet machine Waste plastic recycling compacting silo pellet water ring drawing line plastic pellet machine

Single/double stage granulation line

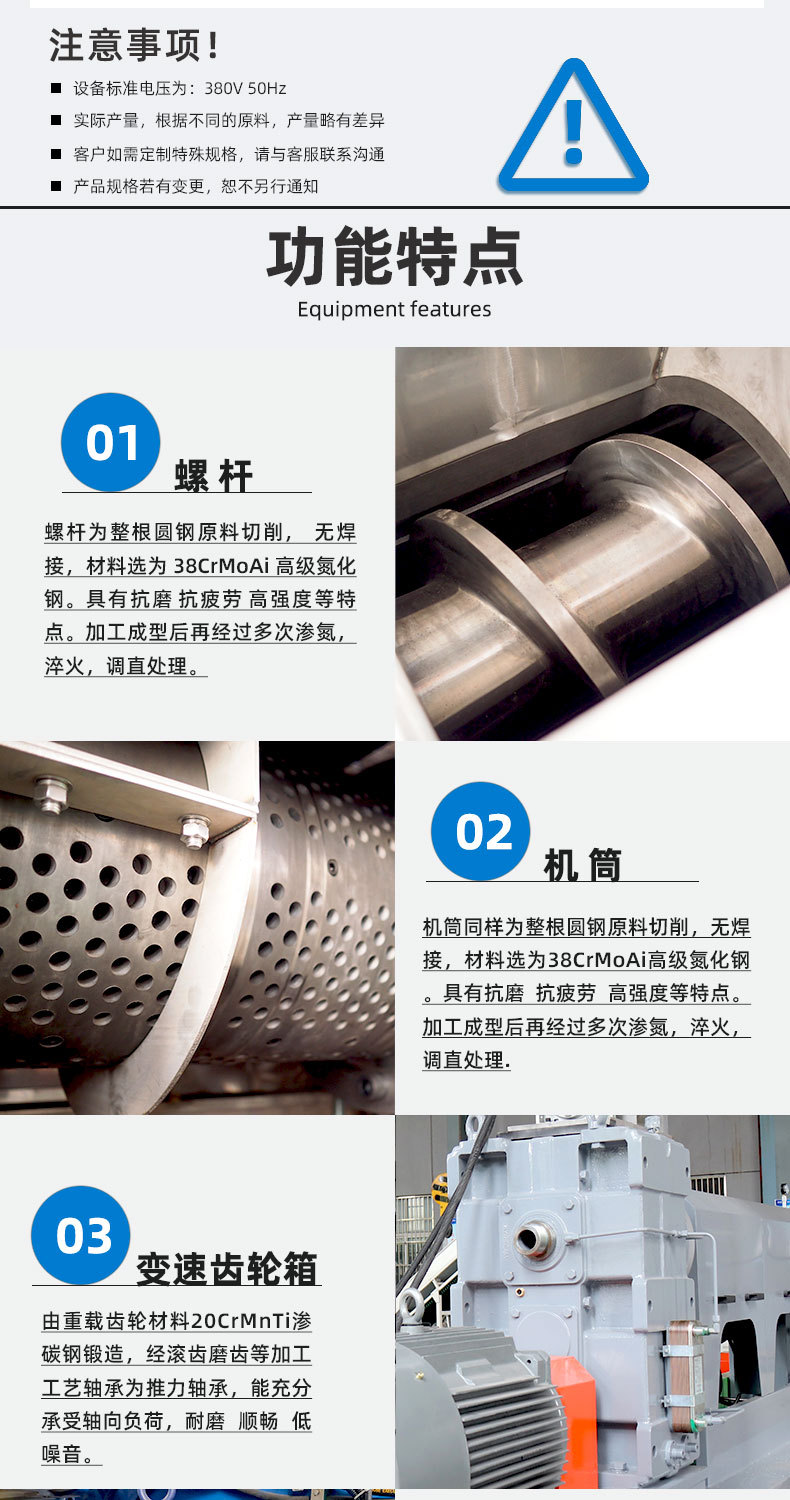

1.Screw: The screw is cut from the whole round steel raw material without welding, and the material is selected as 38CrMoAi high-grade nitride steel. It has the characteristics of anti-wear, anti-fatigue and high strength. After processing and forming, it has been nitriding, quenching and straightening for many times.

2.Barrel: The barrel is also cut from the whole round steel raw material, without welding, and the material is selected as 38CrMoAi high-grade nitriding steel. It has the characteristics of anti-wear, anti-fatigue and high strength. After processing and forming, it has been nitriding, quenching and straightening for many times.

3.Variable gear box: forged by heavy duty gear material 20CrMnTi carburized steel, bearing by hobbing grinding and other processing technology for thrust bearings, can fully withstand axial load, wear-resistant smooth low noise.

4.Power motor: The power of the main shaft power motor is 75-250KW, which needs to be selected according to the materials produced by the customer and the required output per hour

5Cutting method: For different materials, we have two kinds of cutting methods: strip cutting and water ring cutting

6Vibrating screen: high frequency vibration rate, can effectively automatically screen the size of plastic particles, so as to obtain uniform size of plastic particles