Description

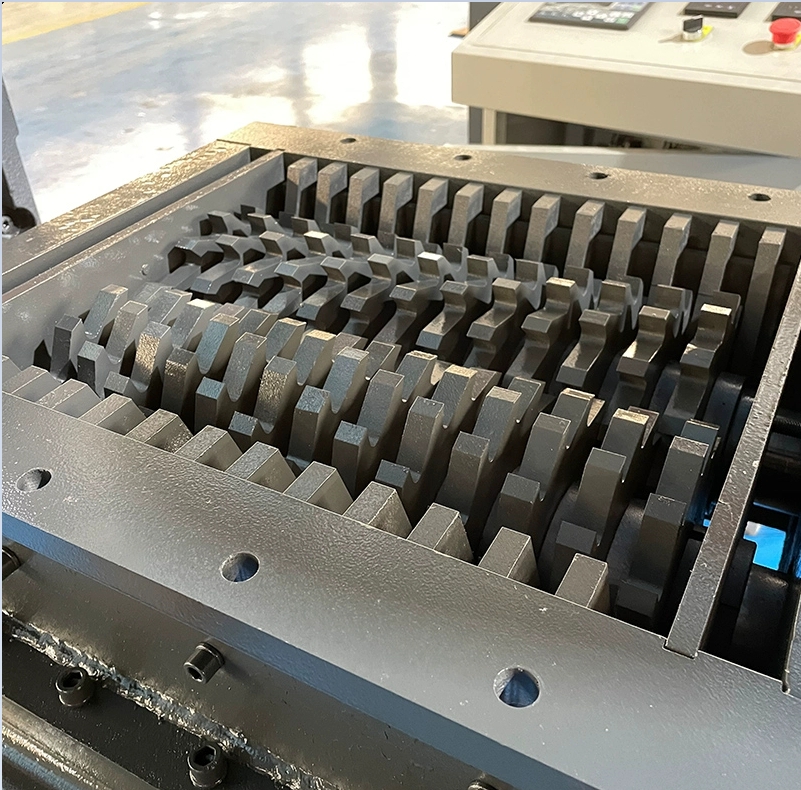

Shredder Plastic metal shredder box Small kitchen waste plastic shredder Metal wood shredder knife box customization

1.The integral chassis has high mechanical strength and precision after heat treatment and high-precision machine tool processing, and is not easy to deform and has stronger bearing capacity, longer service life, stable and durable

2.The main shaft of the tool box is made of high-strength alloy material by multi-process precision machining, which has high wear resistance and long service life.

High strength alloy spindle and blade high precision/high strength/wear resistance/high temperature resistance/good rigidity

Can be customized: shredder small square knife and other shredder accessories

product details

1.Selection: Selection of excellent steel, complete raw materials: 9CRSI, 6CRW2SI, SKD-11H13 and other die steel, the selection of excellent steel is the basis for making excellent products.

2.Forging: After the raw material is heated at high temperature, the air hammer repeatedly forging can make the workpiece material density is good, the quality and density is good, and the dry hammer is refined to produce excellent workpiece blank.

3.Finishing: The use of various CNC machining machinery to ensure accuracy and improve work efficiency. Stable processing quality, high quality, high repetition accuracy, to a large extent to ensure the quality of the blade.

4.Heat treatment: The use of large diameter vacuum quenching furnace for heat treatment, uniform heat treatment, accurate hardness, stable performance. The excellent heat treatment process can modulate the material properties of the workpiece to a better state.

5.Fine grinding: The use of excellent grinding machine cutter, high sharpness, good parallelism, long service life. The finished products produced are neat and of high quality.