NANJING LETERS MACHINERY EQUIPMENT CO., LTD

tobysunnj@gmail.com

One stop service

+86 15854503282

Cheap price

15854503282

Best quality

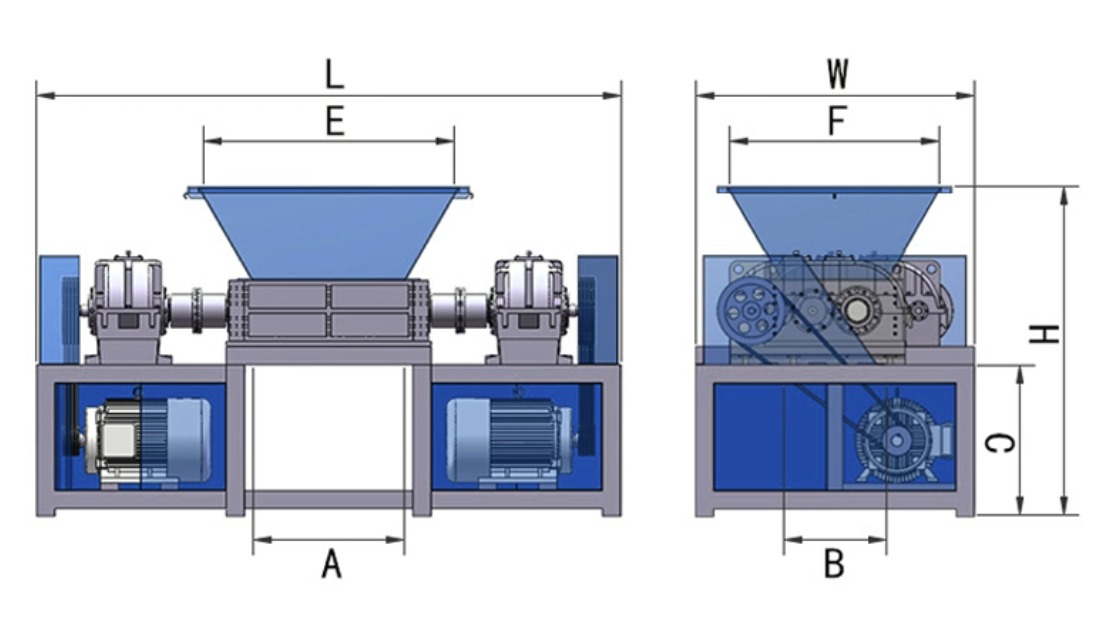

Small double shaft shredder

Shredder can generally be used to tear more difficult to break plastic, rubber, large tires, large nylon material, plastic head material, auto bumper, large fish net, large pipe, fiber, paper, wood, electrical parts, cables, PET bottles, cardboard, circuit boards, wood, plastic buckets and other solid objects. Shredder is also called scrap metal shredder, two-axis shredder, wood shredder, tire shredder, plastic shredder, pipe shredder, garbage shredder, circuit board shredder, rubber shredder, aluminum shredder, etc. The main function of the equipment is to squeeze large pieces of material and large diameter drum metal materials that are inconvenient to transport through the cutting of the shredder, and tear into sheet materials that meet the requirements.

Single double shaft crusher Wood plastic waste scrap iron shredder Plastic double motor small shredder can be customized

Shredder: Also known as shredder crusher crusher, through cutting, tearing and extrusion to reduce the size of the shredded material.

hredder working principle:

shredder adopts gear motor directly connected worm gear, directly installed on the drive shaft of the crusher, through the size of the gear change to the drive shaft, so that the main drive shaft on the spiral tooth cutter to form relative motion. The helical tooth cutter on the main drive shaft is staggered, so that the material is squeezed, torn and cut at the same time, so that the material is broken.

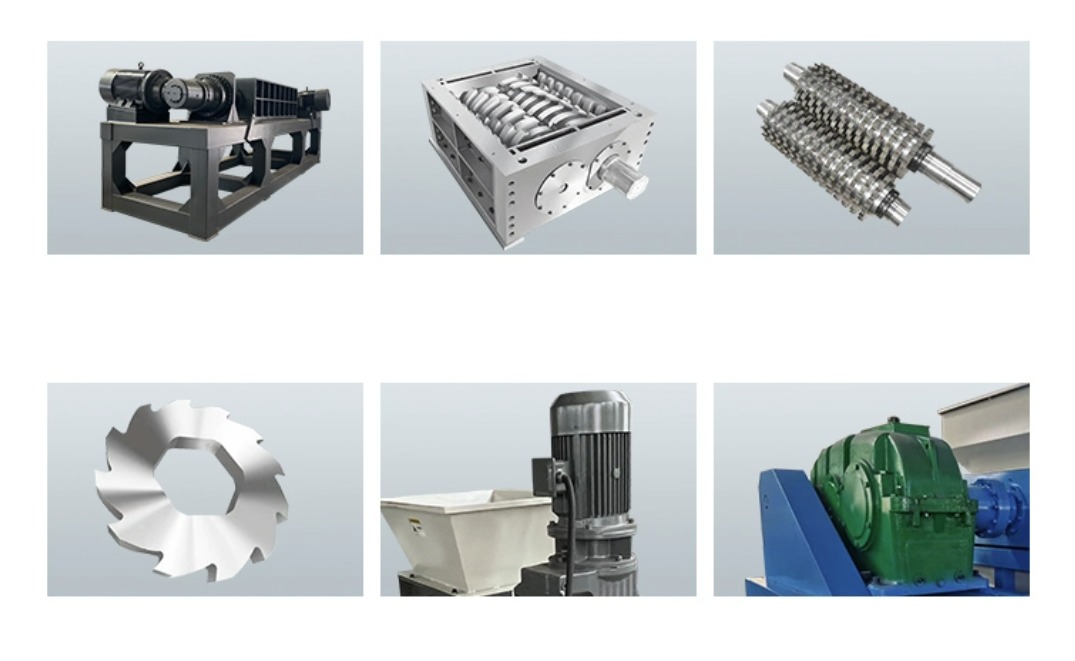

Shredder parts:

1. The main body of the crusher equipment adopts high quality steel plate welding stress relief treatment/overall machining to ensure the stability of the equipment in the long-term heavy load.

2. Moving tool/fixed knife moving tool material is made of alloy tool steel forging blank, precision machining, multiple heat treatment and low temperature freezing heat treatment technology, the overall toughness and hardness can be repeatedly repaired and used to ensure cutting performance and service life. The fixed tool is installed with hook type, which optimizes the tool change function and makes the tool maintenance and change more efficient.

3. The bearing/seal bearing seat adopts the split and disassembly type, which can quickly remove the moving tool, fixed tool, bearing and other parts easy to maintain and replace the tool. The unique sealing structure effectively blocks the contact between the broken material and grease, and protects the bearings and gears when dealing with liquid materials.

4, the tool shaft is processed with high-strength and heavy-duty steel, which more reasonably matches the tool to provide powerful power for cutting.

Dual shaft shredder performance characteristics:

1, this product for a shaft crusher difficult to powder bulk material, basket material, pipe, plate, wood, tires, scrap metal barrels, large roll film can be broken;

2, thick plate precision machining of the composite structure frame, large Angle hexagonal column of strong rotation shaft, large caliber solid input hopper, so you can rest assured that large raw materials:

3, in the thickness, shape, arrangement and other aspects of the design and processing rotary knife, strong shear force, sharp blade, can be broken efficiently;

4, low speed operation, low noise, less dust; 5, the tool is made of special alloy steel, strong and durable.

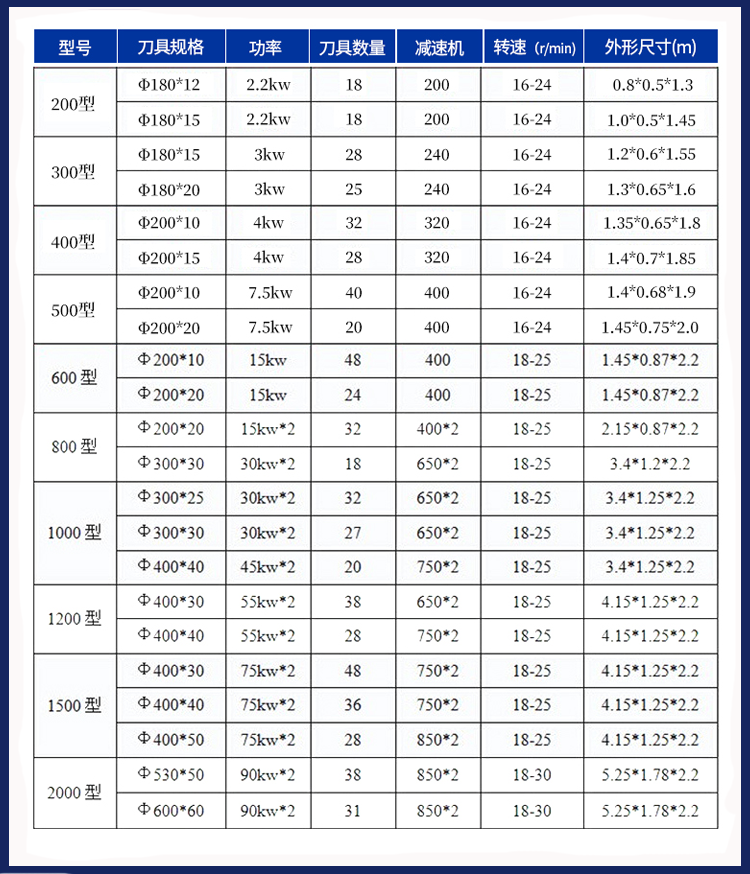

Product model

1. The transmission parts of the shredder are connected with couplings to reduce vibration and protect the spindle and reducer.

2.Shredder gearbox adopts steel plate welding, high precision, good contact, low noise, long service life.

3.The shredding machine adopts all copper core motor to reduce energy consumption and long service life.

4.Shredder blade through forging, annealing, heat treatment, tempering, heat preservation, cutting, fine grinding.